Product Description

The Gold Grinding Machine (wet pan mill), which is named by the diameter of grinding roller, is mainly applied for grinding of gold, silver, lead, zinc, iron, molybdenum, copper, antimony, and so on. Among the models, model 1200 is the most popular one.

As an excellent equipment to work replacing the ball mill, the Gold Grinding Machine (wet pan mill) has been very popular and widely applied by Small and Medium Enterprises because of its small investment, high yield, low production cost, low power, and good benefits.

As an excellent equipment to work replacing the ball mill, the Gold Grinding Machine (wet pan mill) has been very popular and widely applied by Small and Medium Enterprises because of its small investment, high yield, low production cost, low power, and good benefits.

Main Features

-

Wet pan mill suit for mineral processing after the installation is completed to gold grinding machine groove bottom 5 kilograms of mercury begins normal operation.

- Each class receive once the Sands, the shift added to 1 kg of mercury to receive the grind at the end of the Sands and mercury, the mercury received gold equipment, with a relatively high density of red cloth mercury screwed out to the package, open the red cloth which left Sands. One kilogram of mercury each class started on it. Containing one is grasping the cloth of gold or grab the gold behind the blanket and put on the mercury board can receive the gold.

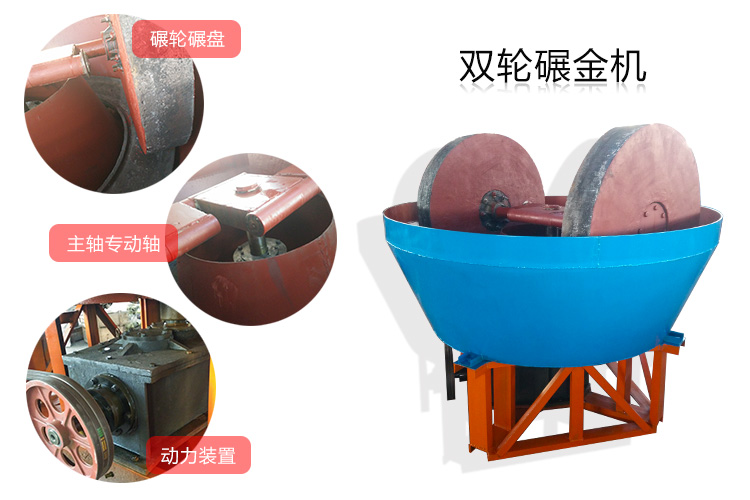

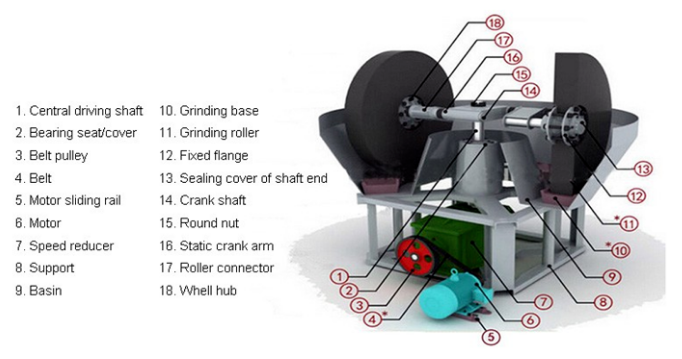

Structure

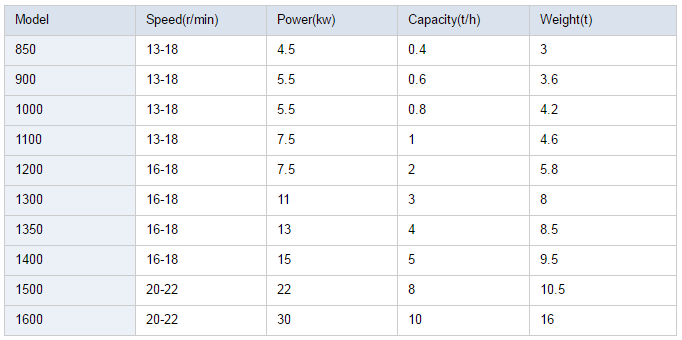

Technical Parameter