Product Description

Ball mill is the key equipment for smash the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grind able materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry. The Ball mill can grind various ores and materials with dry type or wet type.

Working Principle

The ball mill is a horizontal cylindrical rotating device, with outer gears transmission, two warehouses and a grate ball mill. The materials get into the first warehouse through the feeding quill shaft from the feeding device evenly, with the step scale board or the corrugated scale board in the warehouse loaded with different sizes of steel balls. The centrifugal force produced by the rotation of the cylinder raises the steel balls to a certain height, which then fall down, thus making a thumping and abrading to the materials. The materials after coarse grinding in the first warehouse get into the second warehouse with flat scale board embedded with steel sections through the single monolayer partition panel for further crushing. The powder of the materials will be discharged from the unloading board to finish the grinding work.

Our ball mill is composed by feeding part, discharging part, turning part and driving part(reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbling process and the drum is equipped with wear resistant liner, which has good wear resistance. The machine is with stable and reliable working condition.Moreover, according to different materials and discharging methods,there are dry ball mill and wet ball mills for choice.

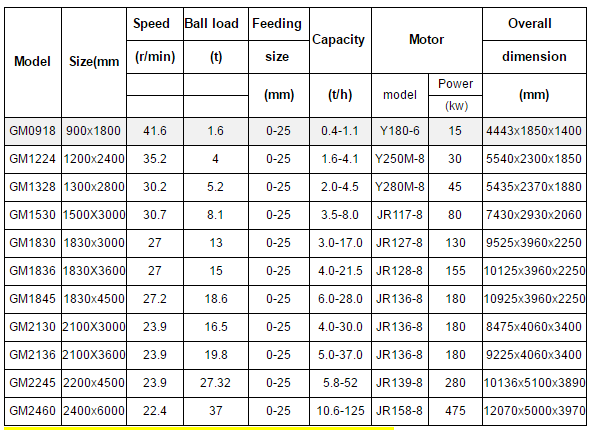

Technical Parameter

Application

Ball Mill is widely used for the dry or wet grinding of all kinds of ores and other grindable materials in the production industries of kaolin, quartz, feldspar, cement, silicate product, new building material, refractory, fertilizer, ferrous metal,non-ferrous metals and glass ceramic industry. etc.

Packaging & Shipping