Product Description

The log washer carries out mixing, washing, separating, and desliming. With a washing pressure less than 147-196kpa, it is also suitable for washing building materials in construction and power station applications. The gear transmission parts of our mine washing machine are separated from stones, water and sands, which greatly reduces the error rate of our spiral washing machine.

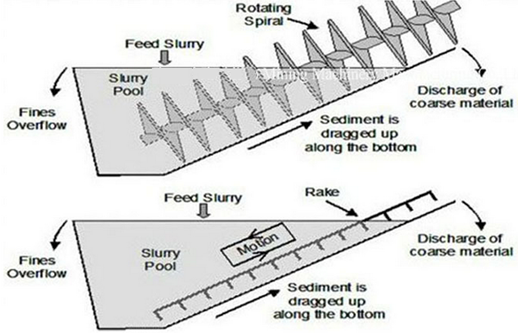

Structure

The log washer drives the spiral stirring shaft depending on speed reducer and rotating in different directions. The minerals feeding into tank were washed by water and stirred strongly by blades. The sewage was overflowed at the end of tank, the cleaned minerals were lifted up along the blade and discharged at the beginning of tank .

When the sand washing machine is running, the motor drives the impeller slowly turning through the belt, reducer, after the gear reduce the speed, sand and gravel are washed into the tank to the trough and driven by the the impeller, with tumbling and grinding each other to remove sand and gravel covered the surface of the impurities, while damages to the water vapor coated layer of sand to facilitate dehydration; at the same time, adding water to form a strong water flow, timely brings small proportion of impurities and foreign matter away and discharged from washing exports of the overflow tank, then finish the cleaning action. The cleaned sand and gravel are brought away from the blade, and finally poured into the out trough by the rotation of the impeller, and then finished the cleaning process.

When the sand washing machine is running, the motor drives the impeller slowly turning through the belt, reducer, after the gear reduce the speed, sand and gravel are washed into the tank to the trough and driven by the the impeller, with tumbling and grinding each other to remove sand and gravel covered the surface of the impurities, while damages to the water vapor coated layer of sand to facilitate dehydration; at the same time, adding water to form a strong water flow, timely brings small proportion of impurities and foreign matter away and discharged from washing exports of the overflow tank, then finish the cleaning action. The cleaned sand and gravel are brought away from the blade, and finally poured into the out trough by the rotation of the impeller, and then finished the cleaning process.

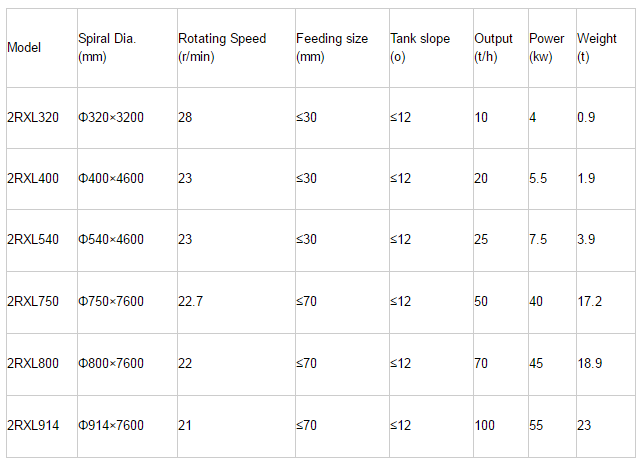

Technical Parameters

Packaging & Shipping