Product Description

Spiral Classifier is widely used to control material size from Ball Mill in the beneficiation process, separate mineral sandand fine mud in the gravity concentration, and clean mud and water in washing mineral process. This machine has features of simple structure, reliable and convenient operation, etc.

Feature

1.Simple structure, stable operation, safe and reliable; 2.The main screw frame electric lifting device of the standard configuration, making the equipment operation and replacement of spare parts more easy. 3.Optimization design of the helical blade, making sure of spare parts to minimize loss.

Structure

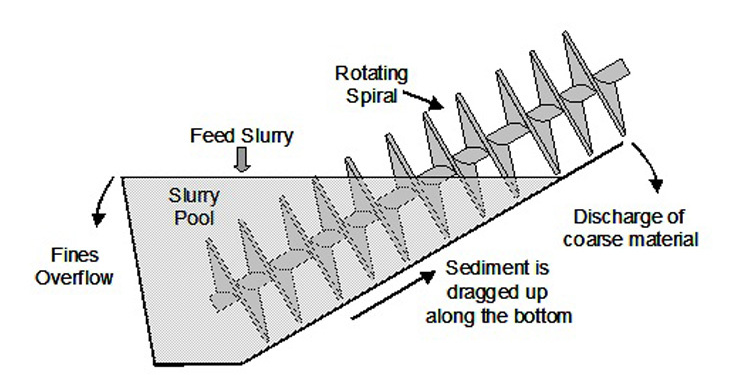

The spiral classifier consists of cell body(Frame), speed reducer(Gear Box), motor, central shaft & Screw, spiral scatters, Weir & support parts. This machine is mainly combined with ball mill during working.

Working principle

The water tank of this gold ore spiral classifier is installed obliquely. The angle of inclination is determined according to equipment configuration of equipment in the process flow. The (left, right) spirals driven by the transmission mechanism rotates in the water tank. The finely grained slurry enters the water bank from the feed inlet at one side and forms one slurry precipitation zone, whose surface area and volume depends on the value of the water tank's inclination angle and the height of overflow edge.

the spirals rotating at a low speed play a certain stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.

Gold mining recovery machine,spiral classifier for mineral separation

If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. The gold ore spiral classifier normally forms closed-circuit operation together with ball mill.

the spirals rotating at a low speed play a certain stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.

Gold mining recovery machine,spiral classifier for mineral separation

If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. The gold ore spiral classifier normally forms closed-circuit operation together with ball mill.

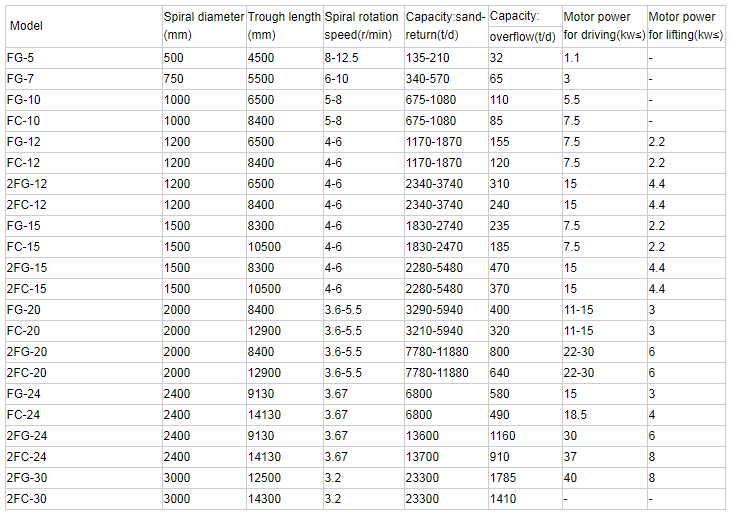

Technical parameter

Application

Spiral Classifier is widely used in mineral processing plant to match with the ball mill and form a closed-circuit circulationto process mining sand, or used in gravity mine-selection plant for classifying sand and mine mud, and grading sand according to the particle size, disliming, dewatering in the mine washing process. FG series Spiral Classifier has simple structure, reliable operation, convenient operation,etc.

The spiral classifier is a kind of classifying machine that adopts the principle of settling speed difference according to different material sizes and specific gravity. fine particles floating in the water overflow out; the coarse ore grain sinks to the bottom of the chase which will be pulled to the upper by the spiral and discharging out.

The spiral classifier is a kind of classifying machine that adopts the principle of settling speed difference according to different material sizes and specific gravity. fine particles floating in the water overflow out; the coarse ore grain sinks to the bottom of the chase which will be pulled to the upper by the spiral and discharging out.